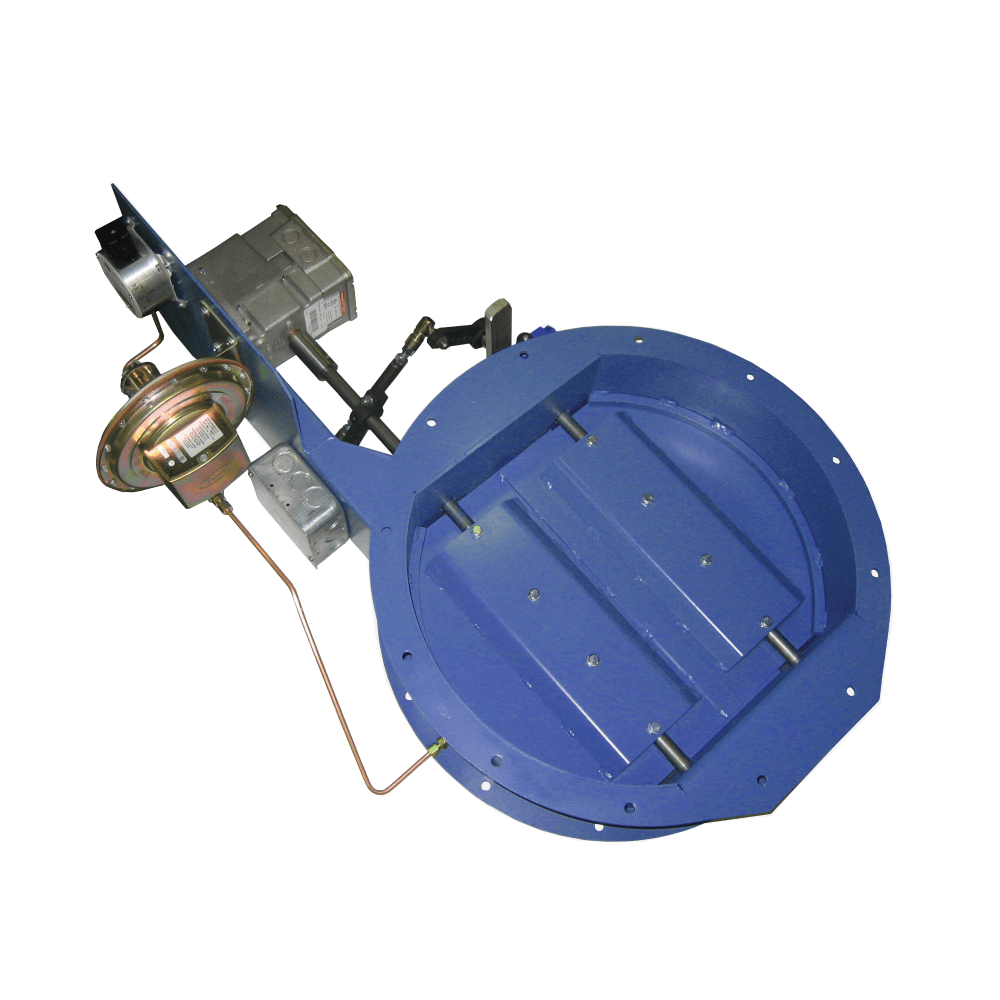

Stack Damper

Description

The Industrial Combustion Stack Damper is designed to control chimney draft. The stack damper can be used as an on-off system, to help reduce boiler standby losses, or with the IC Sequence Draft System to control excessive draft throughout the firing range. This improves heat transfer, combustion efficiency, and reduces incidences of pilot failure. The Stack Damper is a ruggedly built multi-blade damper system, flanged for easy installation in pressure stacks from 12 to 44 in. in diameter. The opposing damper blade design delivers precise draft control. Damper blades are #10 gauge carbon steel plate reinforced and bolted to a 3/4″ diameter cold rolled steel shaft. The shaft is supported by relubricable, high temperature ball bearings with Graphalloy® bushings. The heavy duty cast iron arms and ball joints provide smooth assembly movement. The damper system is driven by a control motor developing between 150 and 600 inch pounds of torque (depending on the size of the damper) and operated by either a 0 – 135 ohm or a 4 to 20 mA signal. A pressure switch and external limit switch are provided for maximum safety, proving damper open before firing of the burner. Maximum temperature rating is 600 °F.

- Fits pressure stacks 12″ to 44″ in diameter

- High temperature bearings

- Reduces boiler standby losses

- Compatible with IC Sequence Draft System

- Pressure/Draft Transmitter mounted to damper assembly